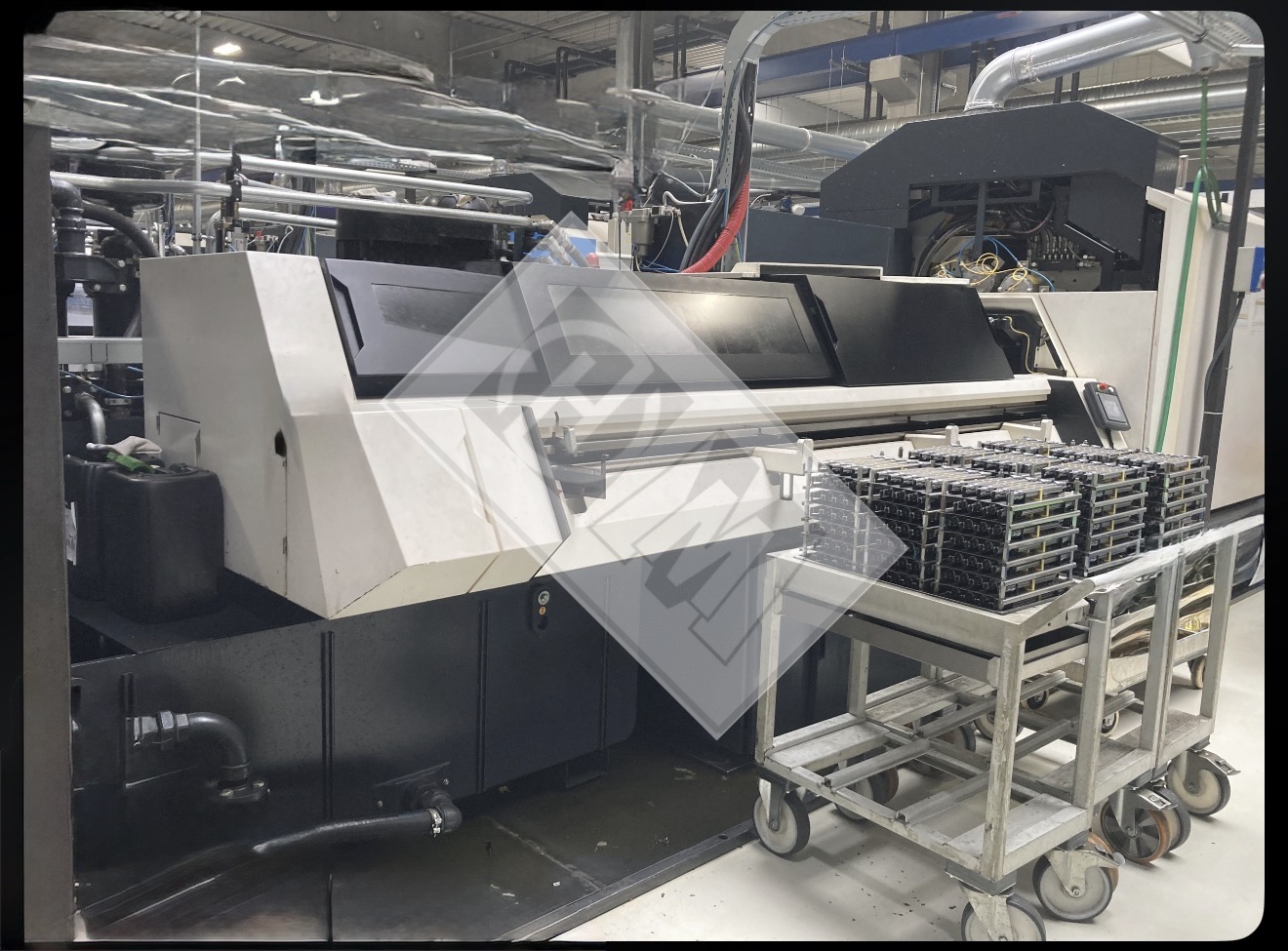

Description

Location: Germany, Baden-Württemberg Southwest

Condition: As good as new

Manufacturer: DMG

Model: MULTISPRINT MS36-2

Year of construction: 2018

Operating hours: 31241

CNC-DMG Gildemeister MULTISPRINT 36 / SWISSTYPE machining up to 170 mm turning length

Year of construction: 2018

Operating hours: 47548

Processing time: 31241

Status: October 2025

Control system: Fanuc 30i B

Maximum flexibility of the MULTISPRINT thanks to its modularity and Y-axes in every position

Use of driven tools on all spindle positions

Y-axis on all spindle positions as standard

SWISSTYPEkit for short and long turning up to 170 mm in length

Chuck or bar machining: bars from 4 to ø 36 mm, chuck components up to ø 50 mm Double-sided and off-centre machining

Machine type: Multi-spindle automatic lathe

SWISSTYPE machining: up to 170 mm turning length

Control: FANUC Series 30i

Maximum flexibility thanks to modularity and Y-axes on all spindle positions

Use of driven tools on all spindle positions

Machining: bars from Ø 4 - 36 mm, chuck parts up to Ø 50 mm

Double-sided and off-centre processing possible

Performance data

Feature Value

Max. Workpiece diameter 36 mm

Max. Workpiece length 170 mm

Max. Bar passage 36 mm

Traverse paths (X / Y / Z) 50 / 100 / 170 mm

Main spindles

Quantity: 6

C-axis (angular resolution): 0.002°

Cross slide: 6 × (X/Y axis)

Travelling distance Z1-Z6: 170 mm (with SWISSTYPE kit)

Max. Rod passage: Ø 40 mm

Speed: up to 7 500 min-¹

Drive power (100 % ED): 13.3 kW

Torque (100 % ED): 32 Nm

Drum indexing time: 0.65 s

Counter spindle Pick-up spindles

Number: 2 (C-axis with X/Y/Z-axis)

Through-hole: Ø 40 mm

Speed: 7 500 min-¹

Drive power: 13.3 kW

Torque: 32 Nm

Travelling distance (Z7-Z8): 410 mm

Traverse paths (X7-X8 / Y7-Y8): 277 / 312 mm

Rapid traverse speed: 40 m/min

Tool holder on cross slide

Max. Number of tools: 3

Speed: 3 900 / 8 000 / 13 800 min-¹

Drive power (100 % ED): 0.9 kW

Torque (100 % ED): 5.8 / 2.9 / 1.7 Nm

Traverse paths (X1-X6 / Y1-Y6): 50 / 100 mm

Rapid traverse speed: 20 m/min

Carriage for rear machining

Speed (U7-U8): 3 900 / 8 000 / 13 800 min-¹

Drive power: 0.9 kW

Torque: 5.8 / 2.9 / 1.7 Nm

Control display: 15″ colour display (× 2)

Clamping system: Hainbuch TOPlus 40 Achsfix collet chuck

Hinged belt chip conveyor with lifting pump

High-pressure system for oil (filter 50 / 25 µm, pumps 5 / 12 MPa)

Various tool holders

Fire extinguishing system

Bar feeder (surface loader version)

Workpiece loading system

The machine is electrically and mechanically fully functional and can be inspected under power by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

CNC-DMG Gildemeister MULTISPRINT 36 / SWISSTYPE machining up to 170 mm turning length

Year of manufacture: 2018

Operating hours: 47548

Machining time: 31241

Status: October 2025

Control: Fanuc 30i B

Maximum flexibility of the MULTISPRINT thanks to its modularity and Y-axes in every position

Use of driven tools on all spindle positions

Y-axis on all spindle positions as standard

SWISSTYPEkit for short and long turning up to 170 mm length

Chuck or bar machining: bars from 4 to ø 36 mm, chuck components up to ø 50 mm Double rear and off-centre machining

Machine type: Multi-spindle automatic lathe

SWISSTYPE machining: up to 170 mm turning length

Control: FANUC Series 30i

Maximum flexibility thanks to modularity and Y-axes on all spindle positions

Use of driven tools on all spindle positions

Machining: Bars from Ø 4 - 36 mm, chuck parts up to Ø 50 mm

Double rear and off-centre machining possible

Performance data

Feature Value

Max. workpiece diameter 36 mm

Max. workpiece length 170 mm

Max. bar capacity 36 mm

Travel (X / Y / Z) 50 / 100 / 170 mm

Main spindles

Number: 6

C-axes (angle resolution): 0.002°

Cross slides: 6 × (X/Y axis)

Travel Z1-Z6: 170 mm (with SWISSTYPE kit)

Max. bar capacity: Ø 40 mm

Speed: up to 7,500 rpm

Drive power (100% duty cycle): 13.3 kW

Torque (100% duty cycle): 32 Nm

Drum indexing time: 0.65 s

Counter spindle Pick-up spindles

Number: 2 (C axes with X/Y/Z axes)

Through hole: Ø 40 mm

Speed: 7,500 rpm

Drive power: 13.3 kW

Torque: 32 Nm

Travel distances (Z7-Z8): 410 mm

Travel (X7-X8 / Y7-Y8): 277 / 312 mm

Rapid traverse speed: 40 m/min

Tool holder on cross slide

Max. number of tools: 3

Speed: 3,900 / 8,000 / 13,800 rpm

Drive power (100% duty cycle): 0.9 kW

Torque (100% duty cycle): 5.8 / 2.9 / 1.7 Nm

Travel distances (X1-X6 / Y1-Y6): 50 / 100 mm

Rapid traverse speed: 20 m/min

Sled for rear machining

Speed (U7-U8): 3,900 / 8,000 / 13,800 min-¹

Drive power: 0.9 kW

Torque: 5.8 / 2.9 / 1.7 Nm

Control display: 15″ colour display (× 2)

Clamping system: Hainbuch TOPlus 40 Axle-fixed collet chuck holder

Hinged belt chip conveyor with lifting pump

High-pressure system for oil (filter 50 / 25 µm, pumps 5 / 12 MPa)

Various tool holders

Fire extinguishing system

Bar loading magazine (flat loader design)

Workpiece loading system

The machine is fully functional, both electrically and mechanically, and can be viewed under power by appointment.

Subject to changes and errors in the technical data and specifications, as well as prior sale!

Reviews

There are no reviews yet.