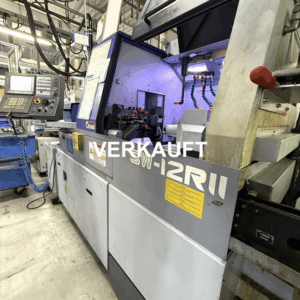

Description

Location: Germany, Baden-Württemberg Southwest

Condition: As good as new

Manufacturer: HANWHA

Model: XD-10 Y2

Year of construction: 2022

Hanwha CNC sliding head lathe XD10 Y2 Top condition

Spindle hours

Operating hours

Year of construction 08_2022

Fanuc control of the 0i series

Hanwha CNC sliding headstock lathe XD10 Y2 with Fanuc control of the 0i series

The Hanwha CNC sliding headstock lathe XD10 Y2 is a high-precision sliding headstock lathe with integrated Fanuc control of the 0i series, designed for machining small diameters in series production. It has a main spindle, counter spindle, extensive tooling and accessories for efficient production processes.

Main spindle

Maximum turning diameter: 10 mm

Maximum spindle bore diameter: 15 mm

Maximum speed: 15,000 rpm

Maximum power: 3.7 kW (built-in motor)

Stroke Z1: 155 mm

Synchronised guide bush unit: Type F853

Collet chuck: Type 120E

Counter spindle

Maximum speed: 10,000 rpm

Maximum power: 1.1 kW

C-axis: Resolution 0.001°

Maximum tap diameter: 10 mm

Stroke Z2: 180 mm

Collet chuck: Type 120E

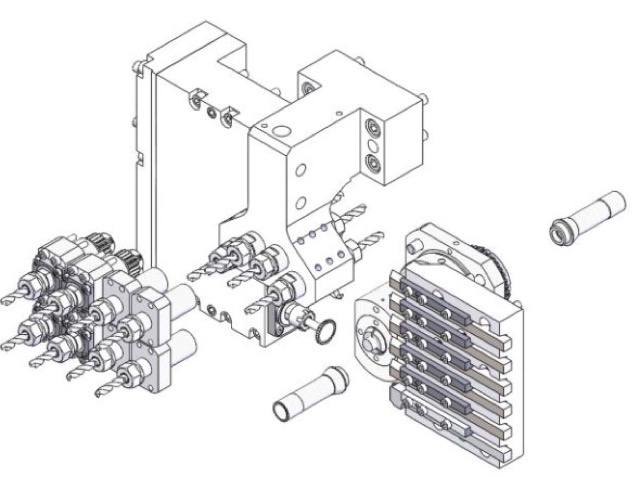

Tool slide X1, Y1:

Tool holder plate for 5 external turning tools (8 x 8 mm)

Cross drilling/milling device:

Quantity: 4 driven drilling/milling spindles (ER11)

Power: 0.55 kW at 10,000 rpm

Front drilling unit for 4 drilling spindles (ER11)

Reverse side processing:

Tool carrier for 8 tools with Y2 axis

4 driven drilling/milling spindles (ER11 modular)

4 fixed drilling/milling spindles (ER11 modular)

Power: 0.55 kW at 9,000 rpm

Rapid traverse: 32 m/min (Z1, Z2, Y, X2); 24 m/min (X1)

Connected load: 12 kVA

Control system

Type: Hanwha Fanuc 0iTF series

Number of axes: 6 (X1, Z1, Y1, Y2, X2, Z2)

Simultaneous 4-axis control

External control panel with handwheel

9.5″ colour monitor (LCD/MDI)

Automatic switch-off function (PowerOff)

Programme check function (test run possible via handwheel)

Parts conveyor belt with collecting tray

Toolbox and service tool set

Coolant tank: 140 litres

Pneumatic blow-out device for the pick-up spindle gripper

Manual and documentation in German and English (maintenance and chip conveyor)

Bar feeder FMB Turbo 2-20 / 3200 mm „C“ (bar diameter: 2-23 mm 1 conversion kit and telescopic tube)

Machine electrically and mechanically fully functional

Complete technical documentation available

The machine can be inspected by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

Hanwha CNC Swiss Type Lathe XD10 Y2 in top condition

Spindle hours

Operating hours

Year of manufacture: 08_2022

Fanuc control of the 0i series

Hanwha CNC Swiss Type Lathe XD10 Y2 with Fanuc Control of the 0i Series

The Hanwha CNC Swiss type lathe XD10 Y2 is a high-precision Swiss type automatic lathe with integrated Fanuc control of the 0i series, designed for machining small diameters in series production. It features a main spindle, sub-spindle, extensive tooling equipment, and accessories for efficient manufacturing processes.

Main Spindle

Maximum turning diameter: 10 mm

Maximum spindle bore diameter: 15 mm

Maximum speed: 15,000 rpm

Maximum power: 3.7 kW (built-in motor)

Z1 travel: 155 mm

Synchronous rotating guide bushing unit: Type F853

Collet: Type 120E

Sub-Spindle

Maximum speed: 10,000 rpm

Maximum power: 1.1 kW

C-axis: Resolution 0.001°

Maximum pick-up diameter: 10 mm

Z2 travel: 180 mm

Collet: Type 120E

Tool Slide X1, Y1:

Tool holder plate for 5 external turning tools (8 x 8 mm)

Cross Drilling/Milling Device:

Number: 4 driven drilling/milling spindles (ER11)

Power: 0.55 kW at 10,000 rpm

Front drilling apparatus for 4 drill spindles (ER11)

Backworking:

Tool carrier for 8 tools with Y2 axis

4 driven drilling/milling spindles (ER11 modular)

4 fixed drilling/milling spindles (ER11 modular)

Power: 0.55 kW at 9,000 rpm

Rapid traverses: 32 m/min (Z1, Z2, Y, X2); 24 m/min (X1)

Connected load: 12 kVA

Control

Type: Hanwha Fanuc 0iTF Series

Number of axes: 6 (X1, Z1, Y1, Y2, X2, Z2)

Simultaneous 4-axis control

External operating panel with handwheel

9.5″ colour monitor (LCD/MDI)

Automatic power-off function (PowerOff)

Programme check function (test run via handwheel possible)

Parts conveyor belt with collection tray

Toolbox and service tool set

Coolant tank: 140 litres

Pneumatic blow-out device for the pick-up spindle collet

Manual and documentation in German and English (maintenance and operating instructions incl. parameter list and test protocol)

Chip conveyor

Bar loader magazine FMB Turbo 2-20 / 3200 mm „C“ (bar diameter: 2-23 mm, 1 conversion kit and telescopic tube)

Machine electrically and mechanically fully functional

Technical documentation completely available

The machine can be inspected under power by appointment.

Changes and errors in the technical data and specifications as well as prior sale reserved!

Reviews

There are no reviews yet.