Description

Location: Germany, Baden-Württemberg Southwest

Condition: Used

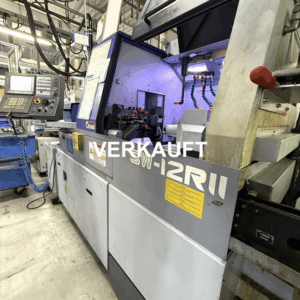

Manufacturer: STAR Micronics

Model: SB-20R_G

Year of construction: 2020

Star Bros. SB20R _G

Year 2020/12

Operating hours approx. 17265

Serial no.: 8794_463

IntNo231023

CNC control FANUC 0i-TD with 7 axes

C-axis on main spindle and counter spindle

Convertible from long to short turner

Main and counter spindle collet type E145

Synchronously driven guide bush unit

Guide bush type T223

HFT (High-Frequency-Turning) makes chip problems a thing of the past

CE Declaration of Conformity

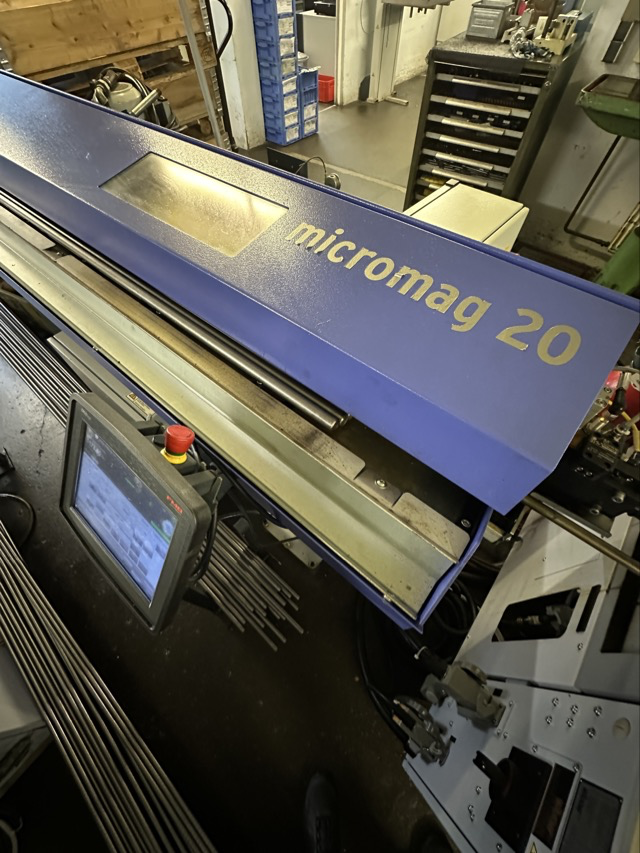

Loading magazine FMB micromag 20 / 3200 "A"

Serial no.: 31-320684 R1845925

Hinged belt conveyor MAYFRAN type MT 10

Kraft and Bauer small extinguishing system and CO2 extinguishing agent container

(6 kg)

SFB-200eco high-pressure system

Serial no.: 12631

Machine dimensions: approx. 2070 x 1177 x 1760 [mm]

Machine weight: approx. 1800 [kg]

Loading magazine dimensions: approx. 5015 x 720 x 1700 [mm]

Loading magazine weight: approx. 600 [kg]

Peripheral HD system dimensions: approx. 1500 x 500 x1000 [mm]

Weight peripheral HD system: approx. 250 [kg]

Dimensions transformer & accessories: approx. 1200 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 80 [kg]

Dimensions chip conveyor & accessories: approx. 1400 x 600 x 600 [mm]

Weight of peripherals & accessories: approx. 120 [kg]

Peripherals & accessories dimensions: approx. 1100 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 80 [kg]

Subject to changes and errors in the technical data and information!

Star Bros. SB20R _G

Year of manufacture: 12/2020

Operating hours: approx. 17,265

Serial no.: 8794_463

Internal no.: 231023

CNC control: FANUC 0i-TD with 7 axes

C-axis on main and sub spindle

Convertible from sliding headstock to fixed headstock turning

Main and sub spindle collet type: E145

Synchronised driven guide bush unit

Guide bush type: T223

HFT (High-Frequency Turning) eliminates chip problems

CE declaration of conformity

Bar feeder FMB micromag 20 / 3200 "A"

Serial no.: 31-320684 R1845925

Hinged belt conveyor MAYFRAN type MT 10

Fire extinguishing system Kraft & Bauer with CO₂ container (6 kg)

High pressure unit SFB-200eco

Serial no.: 12631

Machine dimensions: approx. 2070 x 1177 x 1760 mm

Machine weight: approx. 1,800 kg

Bar feeder dimensions: approx. 5015 x 720 x 1700 mm

Bar feeder weight: approx. 600 kg

High-pressure unit dimensions: approx. 1500 x 500 x 1000 mm

High-pressure unit weight: approx. 250 kg

Transformer & accessories dimensions: approx. 1200 x 700 x 800 mm

Weight: approx. 80 kg

Chip conveyor & accessories dimensions: approx. 1400 x 600 x 600 mm

Weight: approx. 120 kg

Other peripherals & accessories dimensions: approx. 1100 x 700 x 800 mm

Weight: approx. 80 kg

Technical data subject to change without notice. Errors excepted.

Reviews

There are no reviews yet.