Your basket is currently empty!

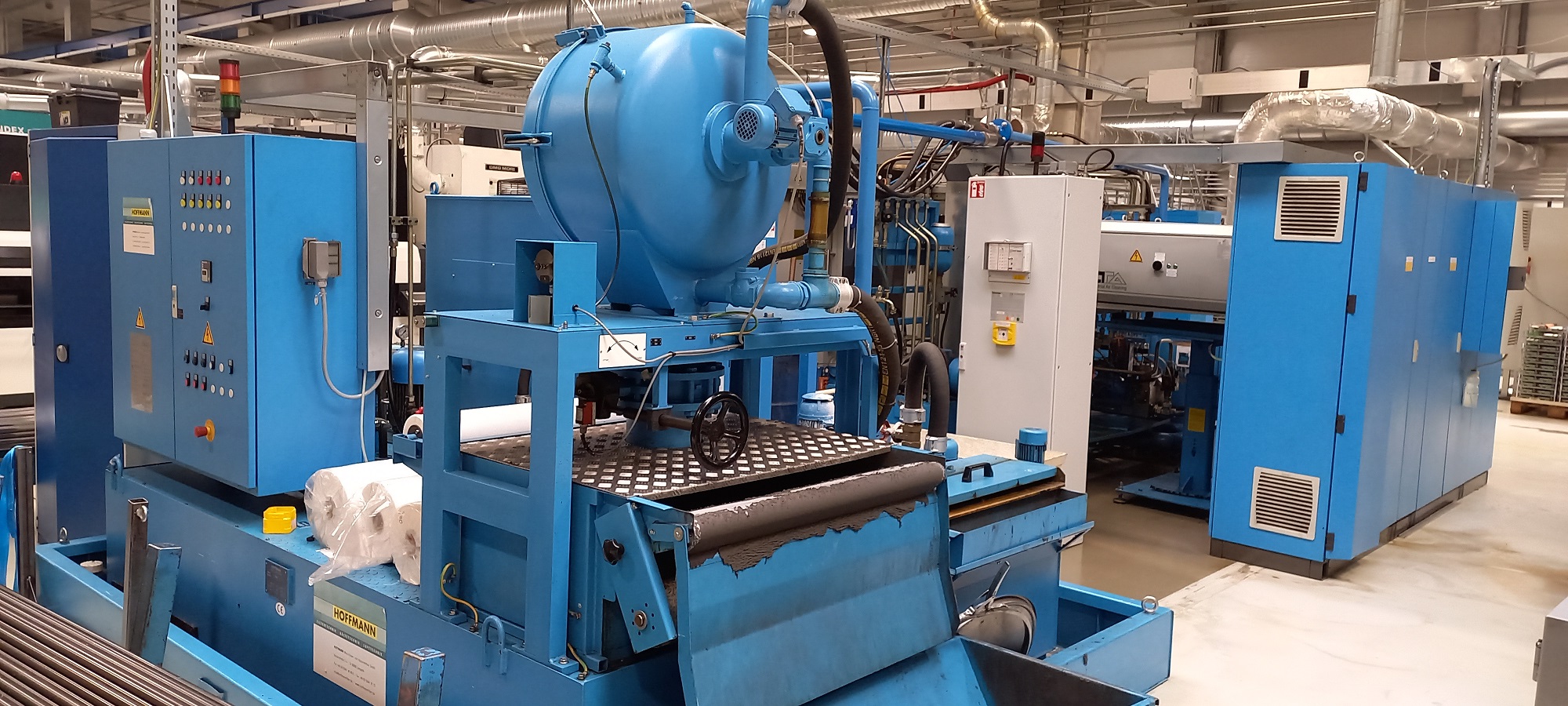

Description

Location: Germany, Baden-Württemberg Southwest

Condition: Used

Manufacturer: Junker

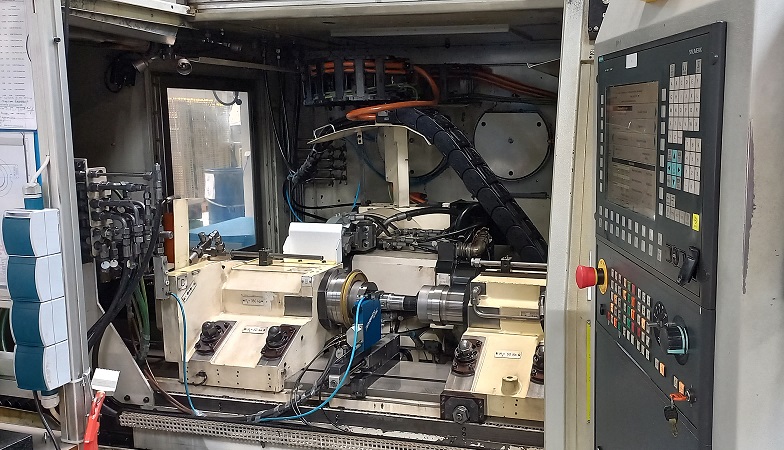

Model: Quickpoint 5000_40

Year of construction: 2006

Machine designation: Cylindrical grinding machine

Manufacturer: Junker

Model: Quickpoint 5000/40

Year of construction: 2006

Condition: as new (exhibition machine)

Functionality: fully functional

Spindle hours: approx. hours

Current Switch-on hours: approx. hours

Description of the

Junker Quickpoint 5000/40 - Tool grinding machine

Year of construction: 2006

Manufacturer: Junker

The Junker Quickpoint 5000/40 is a high-precision tool grinding machine designed for a wide range of grinding tasks, especially for the production of tools and machine components. With its robust design and state-of-the-art control technology, this machine offers exceptional grinding accuracy and high efficiency.

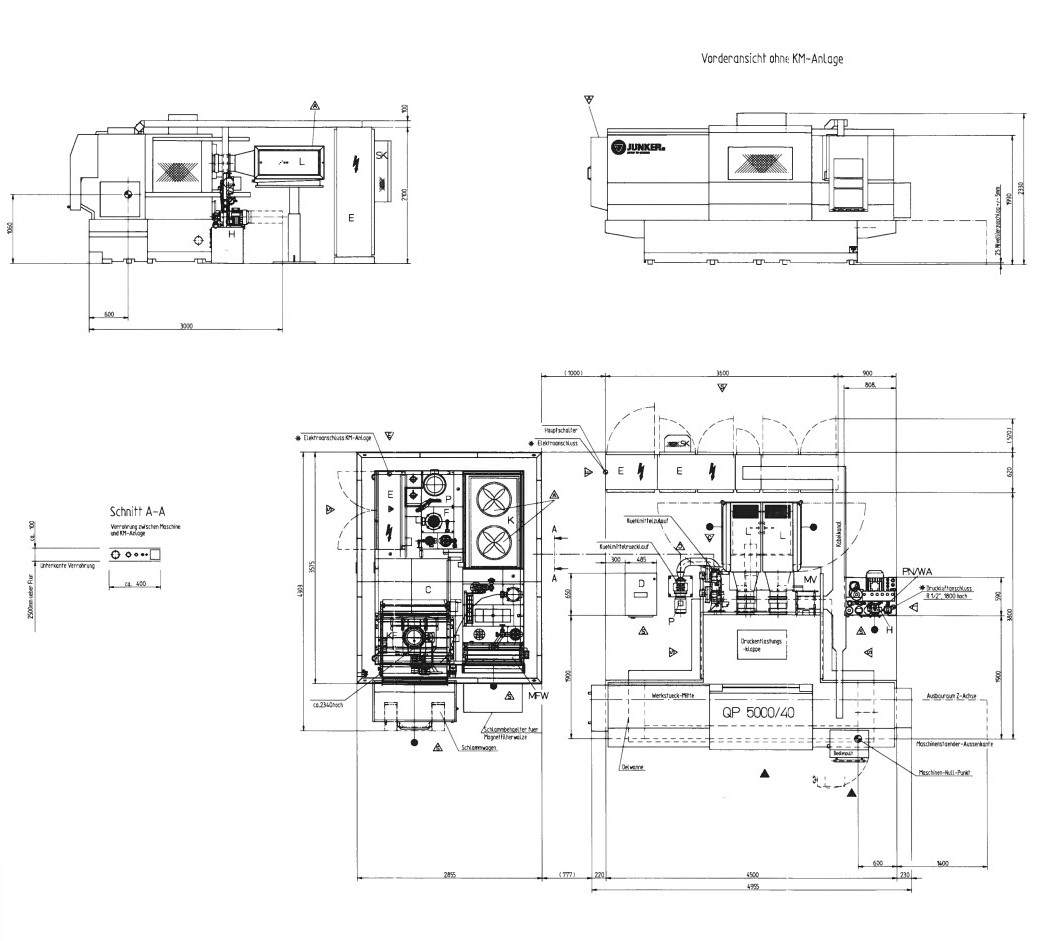

Technical data:

- Power supply: 400V / 50Hz

- Power: 70 kVA

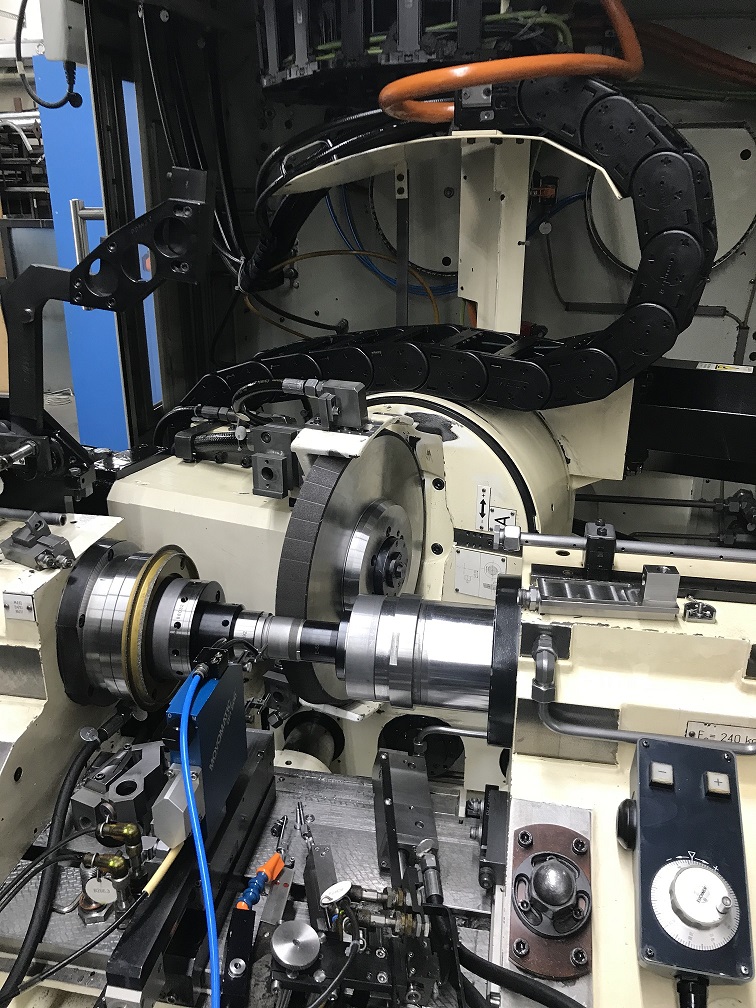

- Workpiece circulation diameter: Max. 280 mm

- Screw-in length of the workpiece: Max. 100 mm

- Workpiece spindle dimensions: 120 x 400 mm

- Special mount: Junker standard collar Ø75 mm

- Workpiece spindle speed: Max. 8000 min-¹

- Tailstock: Manual via chain wheel, centre MK4 or Junker standard collar Ø75 mm, hydraulically adjustable

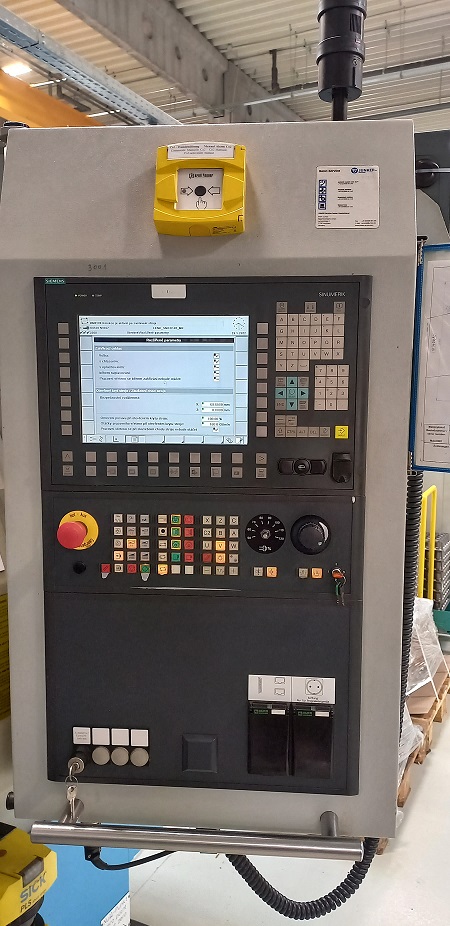

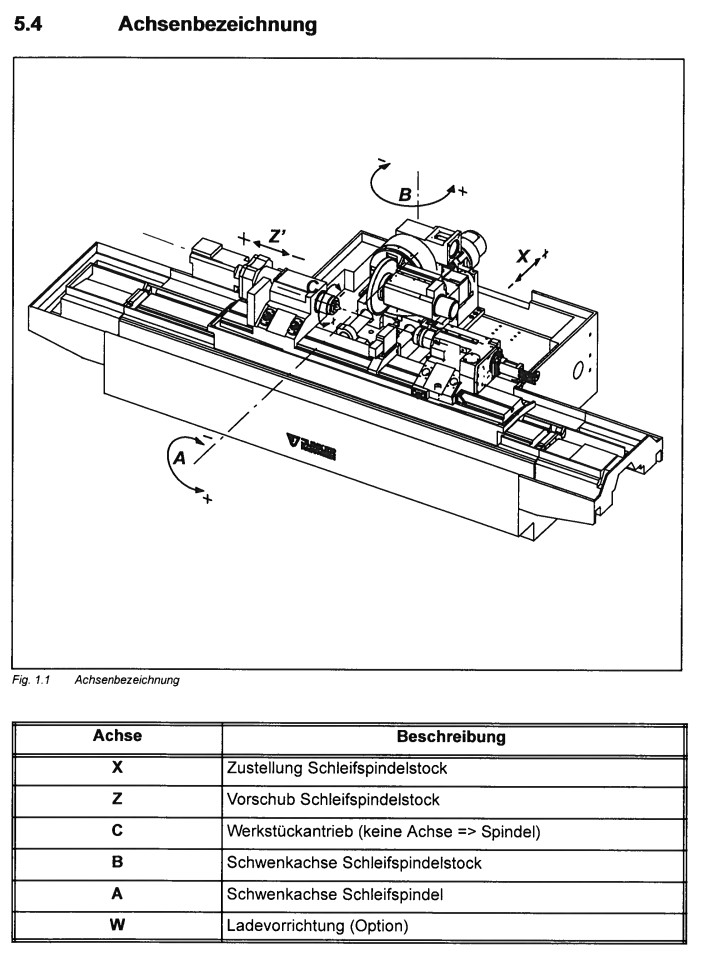

- Z-axis: CNC-controlled, travel max. 1340 mm

- X-axis: CNC-controlled, swivelling angle -0.5°, 0° and +0.5°

- B-axis: CNC-controlled

- A-axis: CNC-controlled

- Spindle dimensions: 180 x 400 mm, flange Ø190 mm, standard collar Ø127 mm

- Spindle drive: 24 kW, max. speed 6000 min-¹

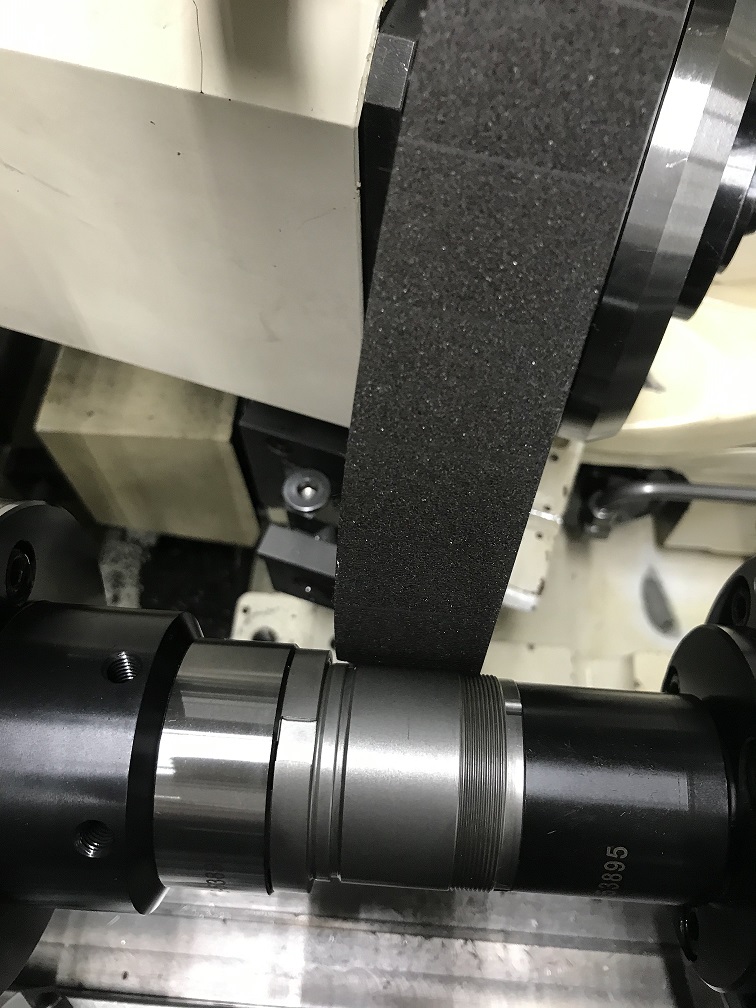

- Grinding disc diameter: Ø400 mm, bore Ø127 mm

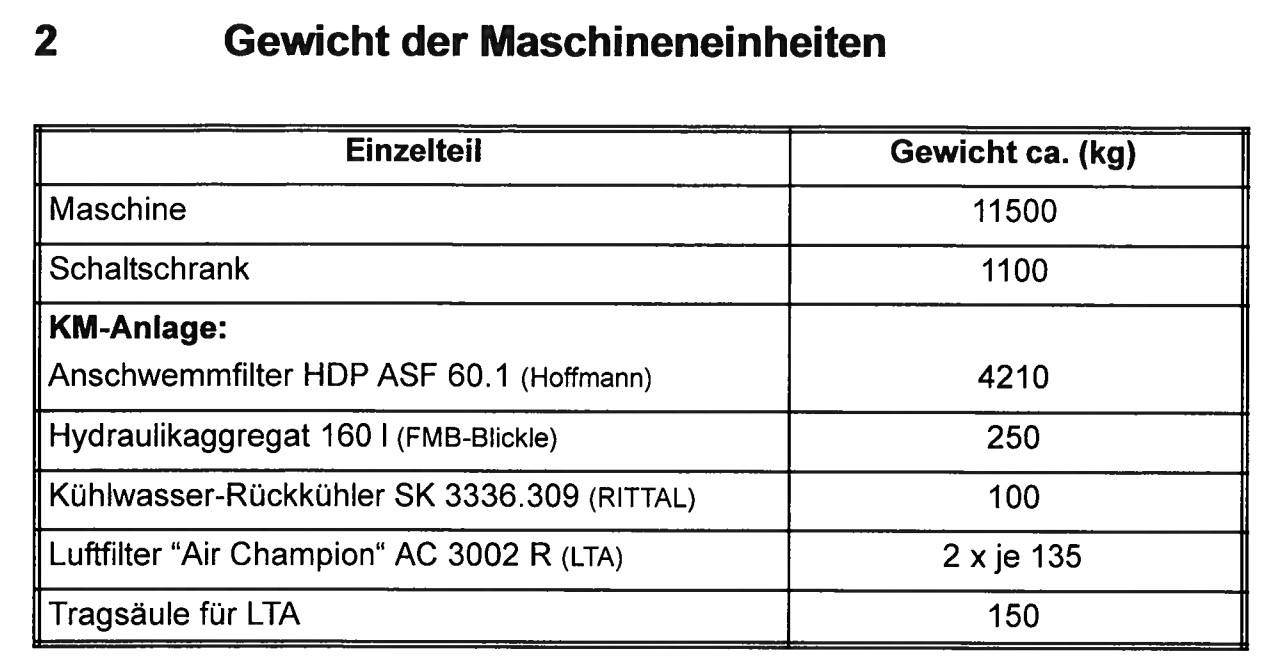

Peripherals and accessories:

- LTA air filter extraction: AC3002R for optimum dust extraction during the sanding process

- Fluid technology: From the company FMB Blickle GmbH, with a pump with a flow rate of Q=24 L/min, tank volume of V=160L, N=1140 rpm and a maximum pressure output of P=60 bar

Machine for grinding impellers and shafts:

The machine is designed for grinding external diameters as well as the double-sided faces on impellers and grinding shafts. It offers high precision and is specially designed for complex grinding tasks.

Current location:

The machine is currently still with our customer in Slovakia.

The machine is fully functional and is in good used condition. It offers high process stability and exact grinding accuracy, ideal for processing carbide, HSS and other materials that require the highest precision.

Special features:

- Automated sanding process for maximum productivity

- Optimised controls for simple operation and fast programming

- Robust construction for a long service life

- High flexibility for different sanding applications

This machine is an ideal solution for companies looking for a reliable and efficient tool grinding machine for their production processes.

For further information or to view the machine under power, please do not hesitate to contact us.

Changes and errors in the technical data and information as well as prior sale reserved!

Junker Quickpoint 5000/40 - Tool Grinding Machine

Year of Manufacture: 2006

Machine Type: Tool Grinding Machine

Model: Quickpoint 5000/40

Manufacturer: Junker

The Junker Quickpoint 5000/40 is a high-precision tool grinding machine designed for a variety of grinding tasks, particularly in the production of tools and machine components. With its robust construction and advanced control technology, this machine offers exceptional grinding accuracy and high efficiency.

Technical Data:

- Power supply: 400V / 50Hz

- Power: 70 kVA

- Max. Workpiece diameter: 280 mm

- Max. Workpiece length: 100 mm

- Workpiece Spindle Dimensions: 120 x 400 mm

- Special adapter: Junker Standard Ø75 mm

- Workpiece Spindle Speed: Max. 8000 rpm

- Tailstock: Manual via chain wheel, MT4 or Junker Standard Ø75 mm, hydraulic adjustable

- Z-Axis: CNC-controlled, travel max. 1340 mm

- X-Axis: CNC-controlled, swivel angles -0.5°, 0° and +0.5°

- B-Axis: CNC-controlled

- A-Axis: CNC-controlled

- Spindle dimensions: 180 x 400 mm, flange Ø190 mm, standard Ø127 mm

- Spindle Drive: 24 kW, max. speed 6000 rpm

- Grinding Wheel Diameter: Ø400 mm, bore Ø127 mm

Peripheral Equipment and Accessories:

- LTA Air Filter Extraction System: AC3002R for optimal dust extraction during the grinding process

- Fluid Technology: From FMB Blickle GmbH, featuring a pump with a flow rate of Q=24 L/min, tank volume of V=160L, N=1140 rpm, and a maximum pressure of P=60 Bar

Machine for Grinding of Wheels and Shafts:

The machine is designed for grinding outer diameters as well as both planar sides of wheels, and for grinding shafts. It offers high precision and is specifically designed for complex grinding tasks.

Current Location:

The machine is currently located at our customer's facility in Slovakia.

The machine is fully functional and in good used condition. It provides high process stability and precise grinding accuracy, ideal for processing carbide, HSS, and other materials that require the highest precision.

Key features:

- Automated grinding process for maximum productivity

- Optimised control for easy operation and fast programming

- Robust construction for long-term durability

- High flexibility for various grinding applications

This machine is an ideal solution for companies looking for a reliable and efficient tool grinding machine for their manufacturing processes.

For more information or to schedule a visit to the machine, we are happy to assist.

Reviews

There are no reviews yet.