Your basket is currently empty!

Description

Location: Germany, Baden-Württemberg Southwest

Condition: Used

Manufacturer: HANWHA

Model: XD20V

Year of construction: 2016

Operating hours: 44682

IntNo231032

HANWHA CNC sliding headstock lathe XD20 V (Y2), year 2016/10

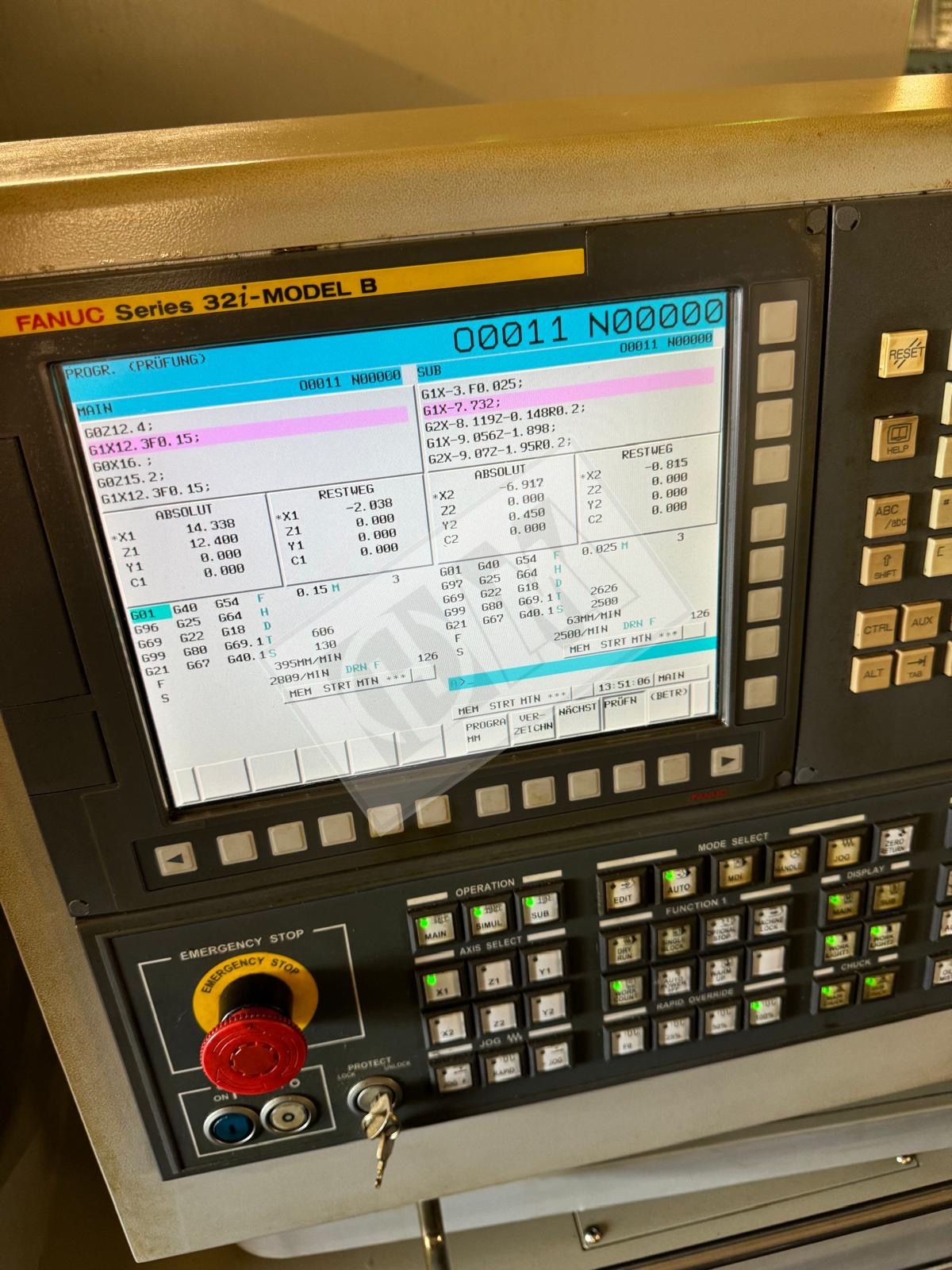

CNC control FANUC 32i-B with 8 axes

Operating hours: 44682

MAIN SPINDLE

Maximum turning diameter: 20 mm

Max. spindle bore diameter: 24 mm

Maximum speed [rpm]: 10,000

Maximum power [kW]: 3.7

C-axis with 0.001°

Stroke Z1 [mm]: 210

Synchronised guide bush unit

Guide bush type: 22.001 / T223

Type of collet chuck: 145E / F25

COUNTERSPINDLE

Maximum speed [rpm]: 8,000

Maximum power [kW]: 3.7

Maximum pick-up diameter [mm]: 20

Max. part length ejection to the front [mm]: 80

C-axis with 0.001°

Stroke Z2 [mm]: 210

Type of collet chuck: 145E / F25

TOOLING OPTIONS

Tool slide X1,Y1:

- Tool holder plate for 6 external turning tools 12 x 12 mm

Cross drilling/milling device:

- Quantity: 5 driven modular drilling/milling spindles

- (Tools 2 x ER16 - 3 x ER11)

- Power: [kW]: 1.0 (S6000)

- Front drilling unit for 5 drilling quills

Back machining with Y2 axis

- Tool carrier for 8 tools

- 4 driven drilling/milling spindles ER16 modular

- 4 fixed drilling/milling spindles ER16 modular

Rapid traverse m/min: 40m/min (X1,Z1,C1,Y1, Z2,C2,X2,Y2)

Connected load [KVA]: 15

ACCESSORIES

Alignment shoes with levelling elements

Service tool kit

Workspace light

Signal lamp (3-coloured)

Safety door switch with locking mechanism

Maintenance and central lubrication unit (1.8 litre lubricating oil volume)

Coolant flow monitoring

Pneumatic blow-out device for the pick-up spindle gripper

Manual and documentation

(Maintenance and operating instructions incl. parameter list and

test report)

LCD/MDI colour monitor

Automatic switch-off function PowerOff

Programme check function (test run possible via handwheel)

Continuous thread cutting cycle

Running time display / parts counter

CF card interface

Tool radius compensation

Absolute reference point

Self-diagnosis function

Interface for JBS

Parts conveyor belt with collecting tray

1° Indexing on pick-up spindle

Chip conveyor with coolant pump

Coolant used by the machine: Oil

CE Declaration of Conformity

Accessories

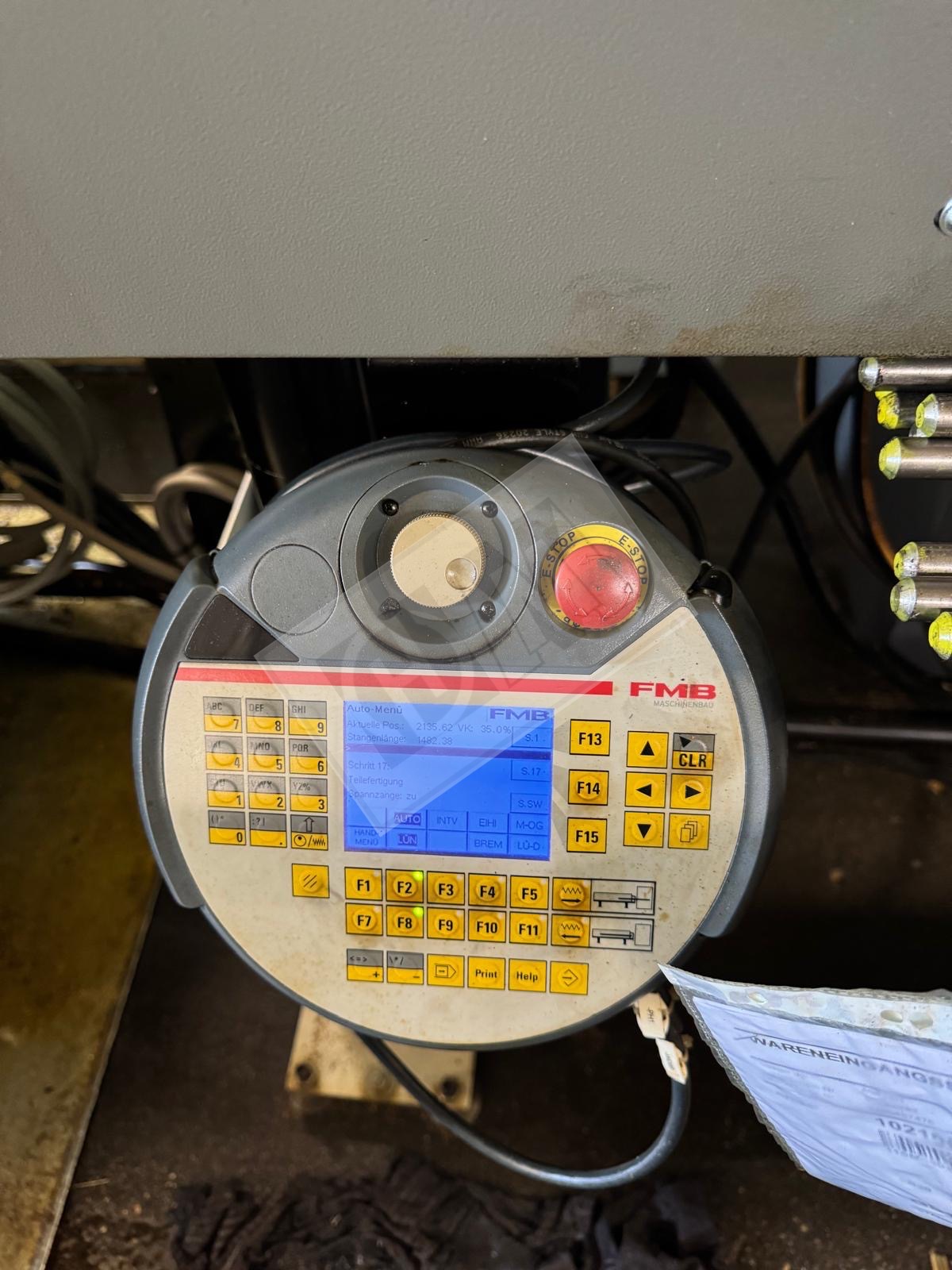

Bar feeder FMB Turbo 2-20

2-23mm/3200mm attachment variant "A"

HD high pressure system SFB M60 eco / 150bar. 24L/min 4valves, duplex filter 2 x 40um

Tank with approx. 280 litres

Hinged belt conveyor

Kraft and Bauer small extinguishing system and CO2 extinguishing agent container

Machine dimensions: approx. 2460 x 1380 x 1730 [mm]

Machine weight: approx. 2900 [kg]

Loading magazine dimensions: approx. 4220 x 620 x 1800 [mm]

Loading magazine weight: approx. 600 [kg]

Peripherals & accessories dimensions: approx. 1900 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 200 [kg]

Peripherals & accessories dimensions: approx. 1900 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 300 [kg]

HD system dimensions: approx. 1660 x 612 x 1500 [mm]

Weight of peripherals & accessories: approx. 300 [kg]

The machine can be inspected by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

Used. HANWHA CNC sliding headstock lathe XD20 V (Y2), year 2016/10

CNC control FANUC 32i-B with 8 axes

MAIN SPINDLE

Maximum turning diameter: 20 mm

Max. spindle bore diameter: 24 mm

Maximum speed [rpm]: 10,000

Maximum power [kW]: 3.7

C-axis with 0.001°

Stroke Z1 [mm]: 210

Synchronous guide bush unit

Guide bush type: 22.001 / T223

Type of collet chuck: 145E / F25

COUNTER SPINDLE

Maximum speed [rpm]: 8,000

Maximum power [kW]: 3.7

Maximum pick-up diameter [mm]: 20

max. part length ejection to the front [mm]: 80

C-axis with 0.001°

stroke Z2 [mm]: 210

Type of collet chuck: 145E / F25

TOOLING OPTIONS

Tool slide X1,Y1:

- Tool holder plate for 6 external turning tools 12 x 12 mm

Cross drilling/milling device:

- Quantity: 5 driven drilling/milling spindles modular

- (tools 2 x ER16 - 3 x ER11)

- Power: [kW]: 1.0 (S6000)

- Front drilling unit for 5 drilling quills

Rear machining with Y2 axis

- Tool carrier for 8 tools

- 4 driven ER16 modular drilling/milling spindles

- 4 stationary drilling/milling spindles ER16 modular

Rapid traverse m/min: 40m/min (X1,Z1,C1,Y1, Z2,C2,X2,Y2)

Connected load [KVA]: 15

ACCESSORIES

Alignment shoes with levelling elements

Service tool set

Work area light

Signal lamp (3-colour)

Safety door switch with interlock

Maintenance and central lubrication unit (1.8 litre lubricating oil volume)

Coolant flow monitoring

Pneumatic blow-out device for the pick-up spindle gripper

Manual and documentation

(Maintenance and operating instructions incl. parameter list and

test report)

LCD/MDI colour monitor

Automatic switch-off function PowerOff

Programme check function (test run possible via handwheel)

Continuous thread cutting cycle

Runtime display / parts counter

CF card interface

Tool radius compensation

Absolute reference point

Self-diagnosis function

Interface for JBS

Parts conveyor belt with collecting tray

1° indexing on pick-up spindle

Chip conveyor with coolant pump

Coolant used in the machine: oil

CE declaration of conformity

Accessories

Bar feeder FMB Turbo 2-20

2-23mm/3200mm attachment variant "A"

HD high pressure system SFB M60 eco / 150bar. 24L/min 4valves, switch-over filter 2 x 40um

Tank with approx. 280L

Hinged belt conveyor

Small extinguishing system Kraft and Bauer and CO2 extinguishing agent tank

Machine dimensions: approx. 2460 x 1380 x 1730 [mm]

Machine weight: approx. 2900 [kg]

Loading magazine dimensions: approx. 4220 x 620 x 1800 [mm]

Weight of loading magazine: approx. 600 [kg]

Dimensions peripherals & accessories: approx. 1900 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 200 [kg]

Dimensions peripherals & accessories: approx. 1900 x 700 x 800 [mm]

Weight of peripherals & accessories: approx. 300 [kg]

HD system dimensions: approx. 1660 x 612 x 1500 [mm]

Weight of peripherals & accessories: approx. 300 [kg]

The machine can be inspected by appointment.

Changes and errors in the technical data and information as well as prior sale reserved!

Reviews

There are no reviews yet.